Features

Options

Application Area

- Cranes

- Conveyors

- Material Handling Equipment

- Mines

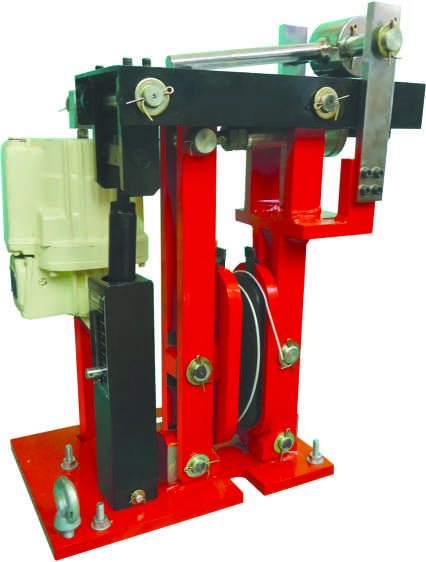

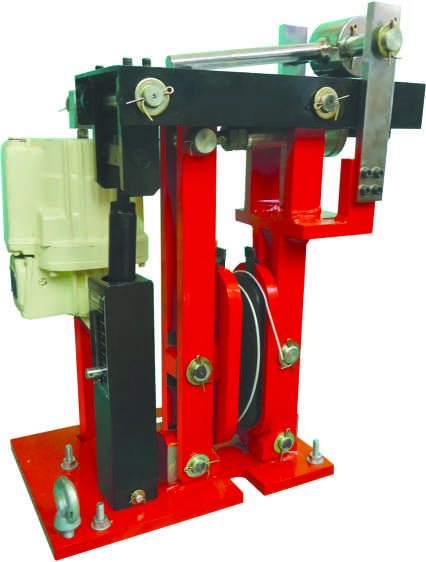

Kateel Electro hydraulic thrustor Disc Brake is a fail safe brake. When power supply is given to the motor, hydraulic pressure builds up inside the thruster and the piston moves up to release the brake. When the power is cut off, hydraulic pressure gets released and the piston moves down, thus moving the brake arm forward allowing the pad to clamp the disc with the spring force and apply the brake.

The Base is fabricated out of Mild Steel IS 2062 suitably drilled and machined for mounting on the machine. The brake arms and Bell crank levers are suitably oxycut to the shape. The edges are properly ground smooth and are drilled to suit the mounting base as well as the brake pads. The entire pin used in the brake for base mounting, thruster mounting, spring mounting are made out of C – 40 material and are machined properly to fit to the levers.

The adjustment screws are also made out of C-40. Provision is made to mount the brake pads on the levers such that the centre of the disc is radially inline with the brake pad ends. Brake adjustment for the minimum clearance between the pad and brake disc is provided. When pads are worn out, the gap between the disc and pad is maintained to the minimum by adjusting this arrangement. The maximum brake pad wear is allowed to 5 mm only on each pad. The adjustment can be made till then and afterwards pads to be replaced. The required braking force can be attained by adjusting the spring force on the operating lever.

© 2019 Kateel Engineering Industry Pvt Ltd. All Rights Reserved